In which polymer materials can DMDPB be used as a flame retardant synergist?

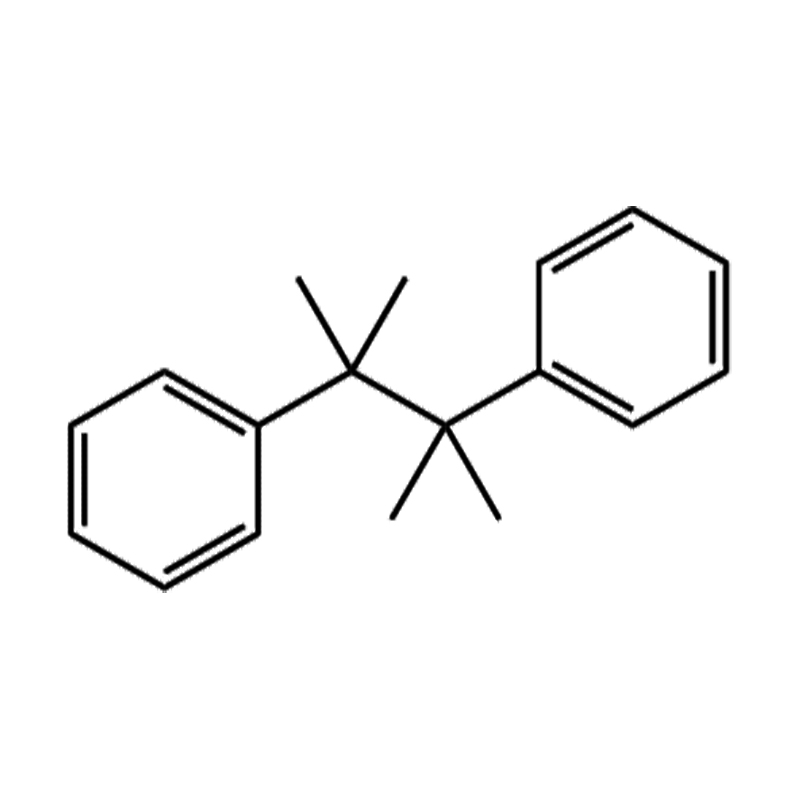

DMDPB is a new flame retardant synergist widely used in the field of polymer materials. Its unique chemical structure and properties enable it to exert significant flame retardant effects in a variety of polymer materials, while reducing the amount of flame retardants and reducing the impact of flame retardants on polymer properties.

DMDPB is particularly prominent in its use as a flame retardant synergist in polyolefin plastics. Polyolefin plastic is an important type of polymer material, widely used in wires and cables, building materials, automobile parts and other fields. As an efficient flame retardant synergist, DMDPB plays an important role in the flame retardant modification of polyolefin plastics. It can effectively improve the flame retardant properties of polyolefin plastics, while reducing the amount of flame retardants and reducing the impact of flame retardants on polymer properties. After adding DMDPB to polyolefin plastics, it can have a synergistic effect with the flame retardant, promoting the dispersion of the flame retardant in the polymer and forming a denser flame retardant layer. This flame retardant layer can effectively isolate oxygen and heat, thereby preventing the spread of flames and the burning of polymers. In addition, DMDPB can also suppress the generation of smoke and toxic gases, improving the safety of polyolefin plastics in fires. In the field of wires and cables, the addition of DMDPB can significantly improve the flame retardant properties of polyolefin cable materials and reduce fire risks. In the field of building materials, the addition of DMDPB can improve the fire resistance of polyolefin-based building materials and improve their safety. In the field of auto parts, the flame retardant synergistic effect of DMDPB can protect the internal wiring and parts of the car from damage in fire and ensure the safety of passengers.

DMDPB can be used as a synergistic flame retardant in both brominated antimony and halogen-free flame retardant systems. Brominated antimony flame retardants are currently one of the most widely used flame retardants, but they are used in large amounts and have a certain impact on the properties of polymers. As a flame retardant synergist, DMDPB can reduce the dosage of brominated antimony flame retardants while maintaining the flame retardant effect, thus reducing the impact on polymer properties. In halogen-free flame retardant systems, DMDPB can also be used as a synergistic flame retardant to improve the flame retardant properties of polymer materials.

DMDPB has high heat resistance and can be commonly used in engineering plastics with higher processing temperatures. Engineering plastics are a type of polymer materials with excellent physical and mechanical properties and chemical stability. They are widely used in aerospace, automobiles, electronics and other fields. However, due to its higher processing temperature, the requirements for flame retardants are also more stringent. As a flame retardant synergist with high heat resistance, DMDPB can maintain stable performance at high temperatures and meet the processing needs of engineering plastics.

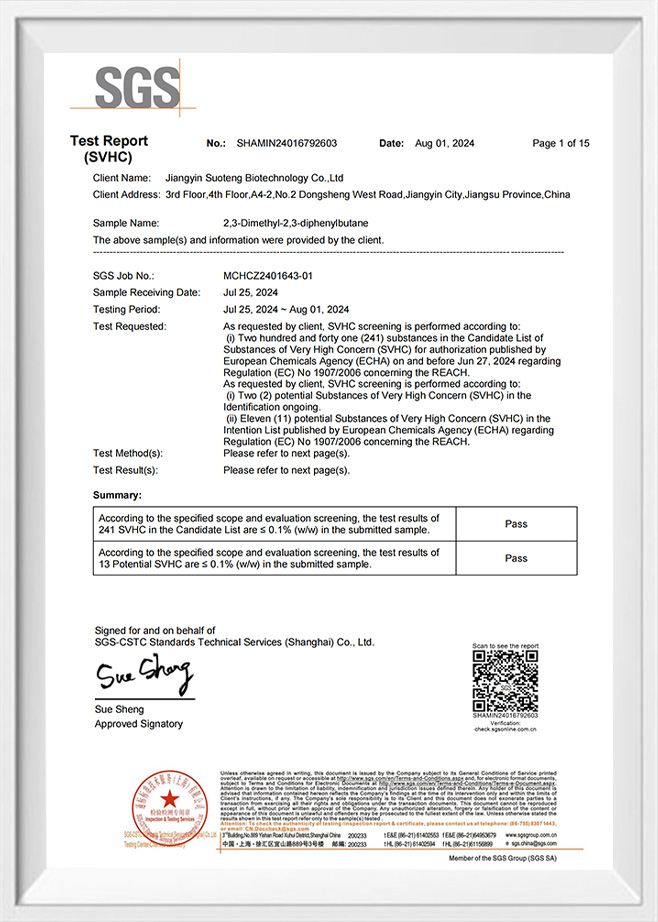

The use of DMDPB also has environmental advantages. It is non-toxic, smoke-suppressing and low-cost, making it a popular additive flame retardant. Compared with traditional flame retardants, the use of DMDPB can not only improve the flame retardant properties of polymer materials, but also reduce production costs and reduce environmental pollution.

English

English 中文简体

中文简体