How does TBPB compare to other organic peroxides in terms of stability and reactivity?

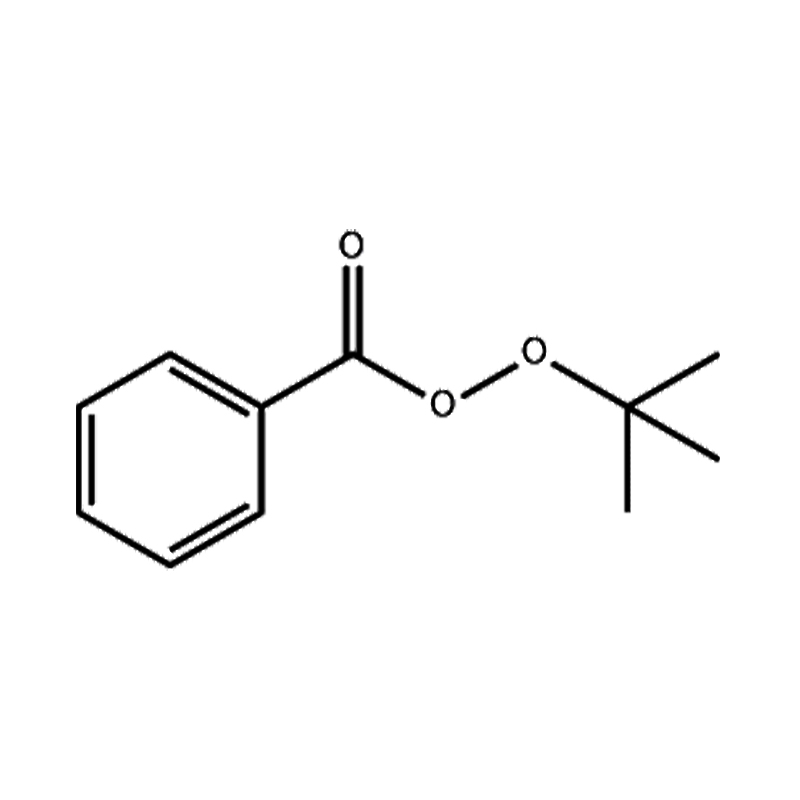

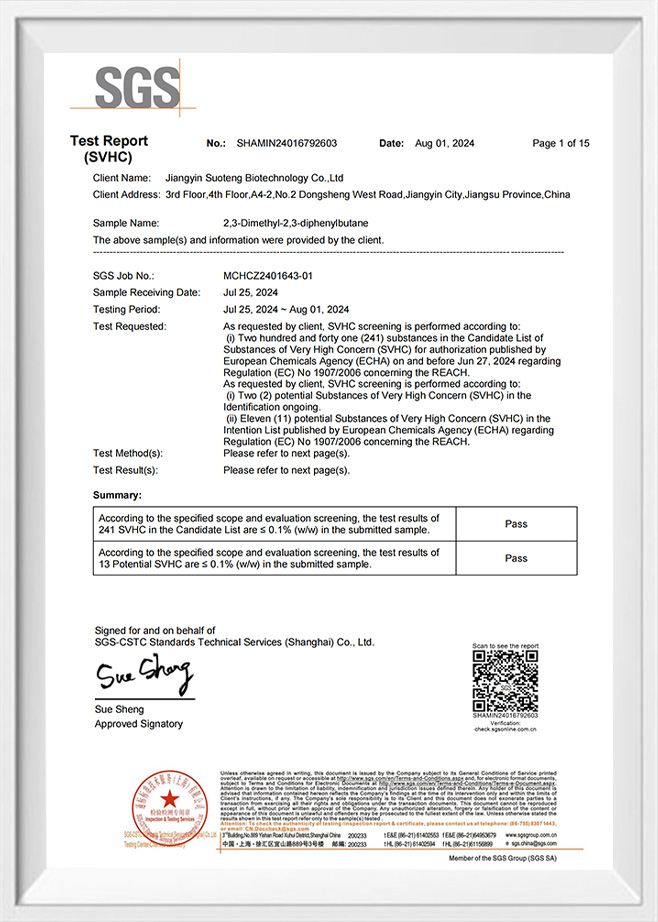

Tert-Butyl peroxybenzoate (TBPB), with CAS No. 614-45-9 and molecular formula C11H14O3, is a slightly yellow liquid organic peroxide known for its high purity (≥98%) and active oxygen content (≥8.07%). Compared to other organic peroxides, TBPB exhibits notable characteristics in terms of stability and reactivity:

Stability: TBPB is relatively stable at room temperature and can be stored under controlled conditions without significant decomposition. Its stability makes it suitable for use in various industrial processes where controlled release of free radicals is required.

Reactivity: TBPB demonstrates moderate reactivity, which is beneficial in polymerization reactions where a controlled rate of polymerization is desired. Its active oxygen content plays a crucial role in initiating polymer chains without excessive heat generation, making it suitable for various polymer and composite applications.

Safety: While TBPB is considered stable under proper handling and storage conditions, it still requires careful handling due to its peroxidic nature. Safety protocols are necessary to prevent hazards associated with organic peroxides.

Boiling Point: With a boiling point of 112°C, TBPB's handling during synthesis and processing can be managed under moderate temperature conditions, which is advantageous in industrial applications.

TBPB's balance of stability and reactivity, along with its specific parameters like high purity and active oxygen content, make it a preferred choice in industries requiring controlled radical polymerization and other related processes.

How to ensure safe storage and handling of tert-butyl perbenzoate in industrial environments to prevent fire and explosion risks?

It is crucial to ensure safe storage and handling of tert-butyl perbenzoate (TBPB) in industrial environments to prevent fire and explosion risks. Here are some key measures and best practices:

1. Storage environment

Temperature control: TBPB should be stored in a low temperature environment (usually 2-8°C) to reduce the risk of decomposition. Avoid direct sunlight and high temperature environment.

Good ventilation: The storage area should have good ventilation to prevent the accumulation of peroxide vapor.

Fire and explosion prevention facilities: The storage area should be equipped with fire and explosion prevention equipment, such as automatic fire extinguishing systems, explosion-proof lamps and firewalls.

2. Containers and packaging

Closed containers: Use suitable, corrosion-resistant closed containers to store TBPB to prevent leakage and evaporation.

Clear labels: Containers should have clear labels indicating the contents, hazards, storage conditions and handling methods.

Regular inspections: Regularly check the sealing and integrity of containers and replace damaged containers in time.

3. Handling and disposal

Personal protective equipment (PPE): When handling TBPB, operators should wear appropriate protective equipment, such as protective gloves, protective glasses and protective clothing.

Antistatic measures: Antistatic measures should be taken in the operating environment, such as using antistatic tools and wearing antistatic clothing, to prevent static sparks from causing explosions.

Avoid friction and impact: Friction, impact and violent shaking should be avoided during handling to prevent peroxide decomposition from causing fire or explosion.

4. Emergency measures

Emergency plan: Develop a detailed emergency plan, including the handling steps for leaks, fires and explosions. Make sure all operators are familiar with the emergency plan.

Firefighting equipment: Storage and operating areas should be equipped with appropriate firefighting equipment, such as dry powder fire extinguishers and carbon dioxide fire extinguishers.

Emergency training: Conduct safety training and emergency drills for employees regularly to improve emergency response capabilities.

5. Regulatory compliance

Comply with regulations: Ensure that storage and handling processes comply with relevant local and international regulations and standards, such as OSHA (Occupational Safety and Health Administration) and EPA (Environmental Protection Agency) requirements. Records and reports: Establish a detailed record system to record the purchase, storage, use and disposal process of TBPB. Report any safety incidents in a timely manner.

English

English 中文简体

中文简体