What are the chemical properties of DBDPE that make it suitable for its intended applications?

DBDPE, or 1,3-di-tert-butyl-2,2-diphenylethane, is a chemical compound that has certain properties that make it suitable for specific applications. Here are some of the chemical properties that could contribute to its use:

1. Stability: DBDPE is a stable compound that does not easily decompose or react under normal conditions, which is important for applications where long-term stability is required.

2. Low Reactivity: It has low reactivity with other substances, which can be beneficial in environments where unwanted chemical reactions need to be avoided.

3. Thermal Stability: It can withstand high temperatures without breaking down, which is useful in applications that involve heat.

4. Non-flammability: DBDPE is non-flammable, making it a safer choice for applications where fire safety is a concern.

5. Chemical Resistance: It may have resistance to various chemicals, acids, and bases, which can be important in industrial applications.

6. Low Volatility: It has low volatility, meaning it does not evaporate easily, which can be advantageous in applications where a substance needs to remain in a solid or liquid state.

7. Compatibility: It may be compatible with a range of other materials, allowing it to be used in composites or mixed with other substances without adverse effects.

8. Physical Properties: While not strictly a chemical property, the physical properties such as density, hardness, and melting point can also influence its suitability for certain applications.

It's important to note that the suitability of DBDPE for specific applications would depend on the exact requirements of those applications, and the properties listed above are general characteristics that could be relevant. For a detailed understanding of how these properties make DBDPE suitable for its intended applications, one would need to consider the specific context and requirements of those applications.

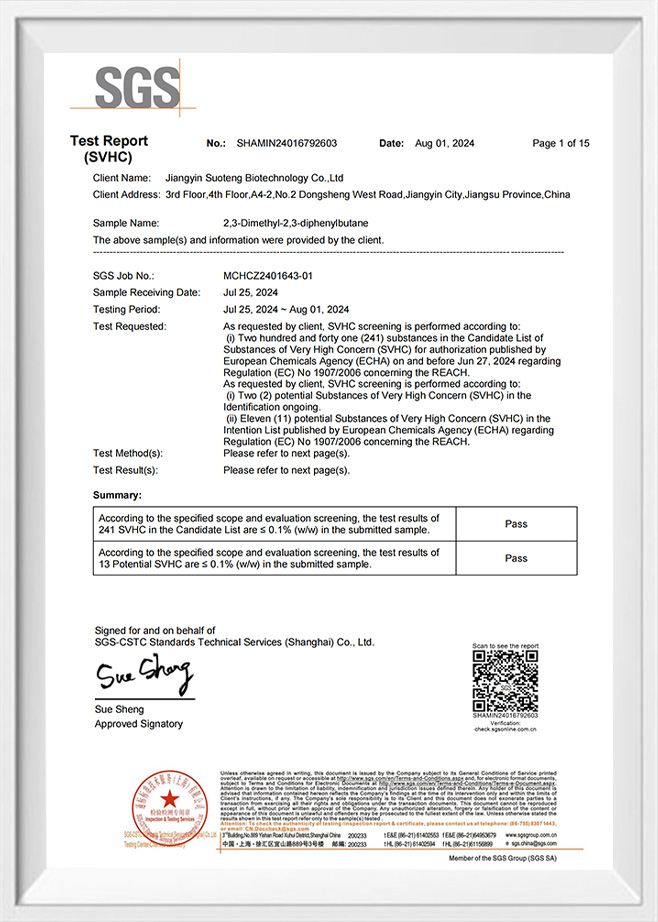

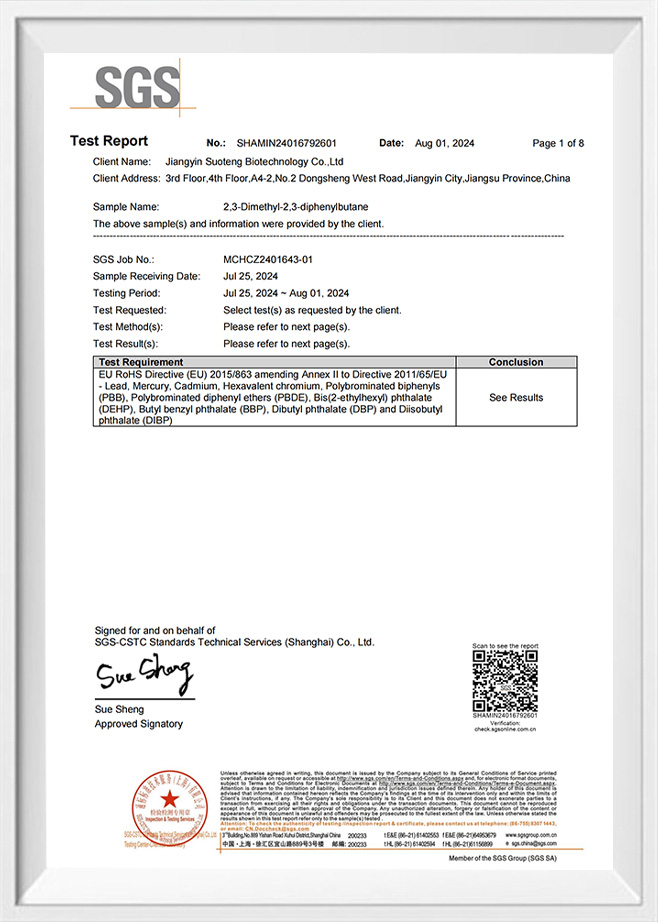

What quality control measures are in place to ensure the purity and consistency of Decabromodiphenyl Ethane(DBDPE)?

Decabromodiphenyl ethane (DBDPE) is a brominated flame retardant used in various applications, including textiles, plastics, and electronics. Ensuring the purity and consistency of DBDPE is crucial for its performance and safety. Here are some common quality control measures that might be in place for DBDPE:

1. Raw Material Testing: Before production, raw materials are tested to ensure they meet the required specifications for purity and composition.

2. In-Process Quality Checks: During the manufacturing process, samples are taken at various stages to monitor the quality and consistency of the product.

3. Batch Control: Each batch of DBDPE is identified and tracked, allowing for traceability in case of any quality issues.

4. Analytical Testing: Various analytical techniques such as high-performance liquid chromatography (HPLC), gas chromatography-mass spectrometry (GC-MS), or inductively coupled plasma mass spectrometry (ICP-MS) may be used to determine the purity and composition of the final product.

5. Standard Operating Procedures (SOPs): Adherence to SOPs ensures that all steps in the production process are carried out consistently and correctly.

6. Environmental Controls: Maintaining controlled conditions such as temperature, humidity, and cleanliness in the production environment can help prevent contamination and ensure product quality.

7. Equipment Calibration and Maintenance: Regular calibration and maintenance of production and testing equipment ensure accurate measurements and consistent product quality.

English

English 中文简体

中文简体