The double-edged sword in the chemical industry - di-tert-butyl peroxide, do you know its safety hazards?

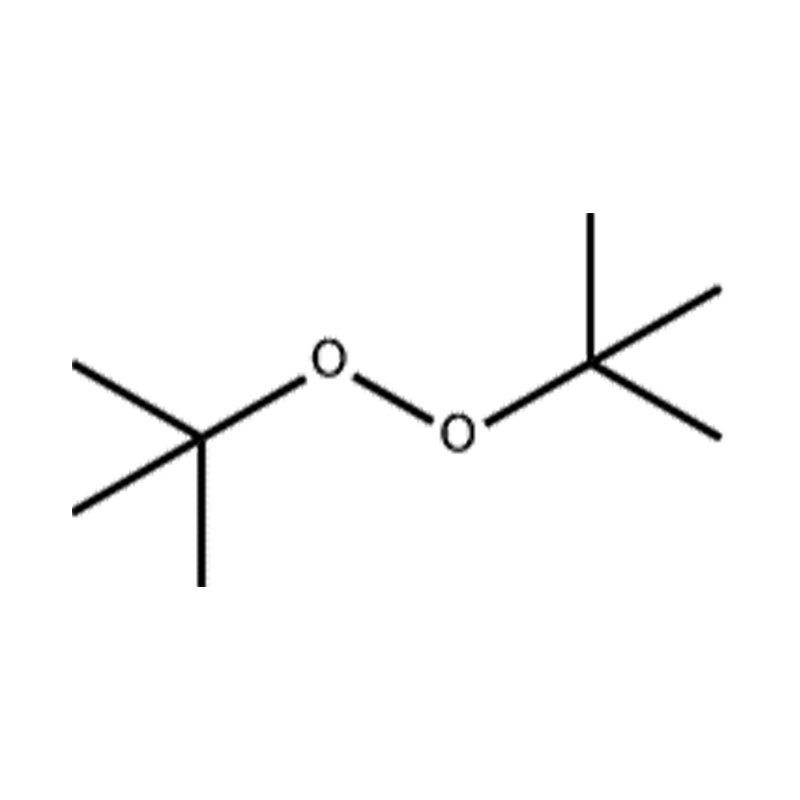

In the chemical industry, organic peroxides have attracted much attention for their unique chemical properties and wide application fields. Among them, di-tert-butyl peroxide (DTBP), known for its chemical formula C8H18O2, CAS No. 110-05-4, is a colorless to slightly yellow transparent liquid, which not only has extremely high purity (Assay ≥99.0%), but also has a certain active oxygen content (≤10.83%).

Di-tert-butyl peroxide (DTBP) is an important organic peroxide with strong oxidizing properties and excellent stability. In chemical synthesis, it is often used as an initiator for synthetic resins, a photopolymerization sensitizer, and a rubber vulcanizer. DTBP can initiate the polymerization reaction of unsaturated compounds, make the polymer chain grow, and thus prepare polymer materials with specific properties.

DTBP can also be used in the field of organic synthesis as an initiator for polymerization reactions to promote the polymerization between monomer molecules to form polymer compounds. In the rubber industry, DTBP is used as a vulcanizing agent. By reacting with the double bonds in the rubber molecules, a cross-linked structure is formed between the rubber molecules, thereby improving the strength and wear resistance of the rubber.

Although di-tert-butyl peroxide is widely used in industrial production, as an organic peroxide, it also has certain safety hazards. DTBP is flammable and has a low flash point (18°C). Special attention should be paid to fire and explosion prevention measures during storage and transportation. DTBP vapor is easy to form an explosive mixture when mixed with air, so the temperature and pressure need to be strictly controlled during use.

In view of the safety issues of di-tert-butyl peroxide, enterprises need to take strict safety management measures during the production process. The sealing and explosion-proof performance of the production equipment should be ensured to prevent the leakage and volatilization of DTBP. During storage and transportation, it should be kept away from dangerous factors such as fire, heat and direct sunlight, and the sealing of the container should be maintained. In addition, enterprises should regularly inspect and maintain production equipment, storage facilities and transportation tools to ensure the safety and reliability of the equipment.

In order to ensure the storage and transportation safety of di-tert-butyl peroxide, enterprises need to take a series of measures. Select storage facilities that meet the requirements, such as cool and ventilated warehouses, and ensure that the warehouse temperature does not exceed 30°C. At the same time, explosion-proof lighting and ventilation facilities should be equipped, and mechanical equipment and tools that are prone to sparks should be prohibited. During transportation, relevant safety regulations and operating procedures should be observed to ensure the safety and stability of transportation vehicles. At the same time, violent vibrations, impacts, and friction that may cause DTBP leakage or explosion should be avoided.

As an important organic peroxide, di-tert-butyl peroxide has a wide range of applications in the chemical industry. However, its flammability and explosiveness also require us to attach great importance to safety issues during use. Ensure the safe use, storage and transportation of di-tert-butyl peroxide by taking strict safety management measures and complying with relevant operating procedures.

English

English 中文简体

中文简体